Watermaker : Basic Operating

As an example to understand the way your water maker starts, let us speak about a starting on the manual mode. Therefore, you turned the switch on “manual”, opened the seacock, switched on the 230V breaker (or 24V on the duo dessalator models), and finally pushed on “Start”. This article explains what happens after.

Let us start by a description of the equipments composing your watermaker :

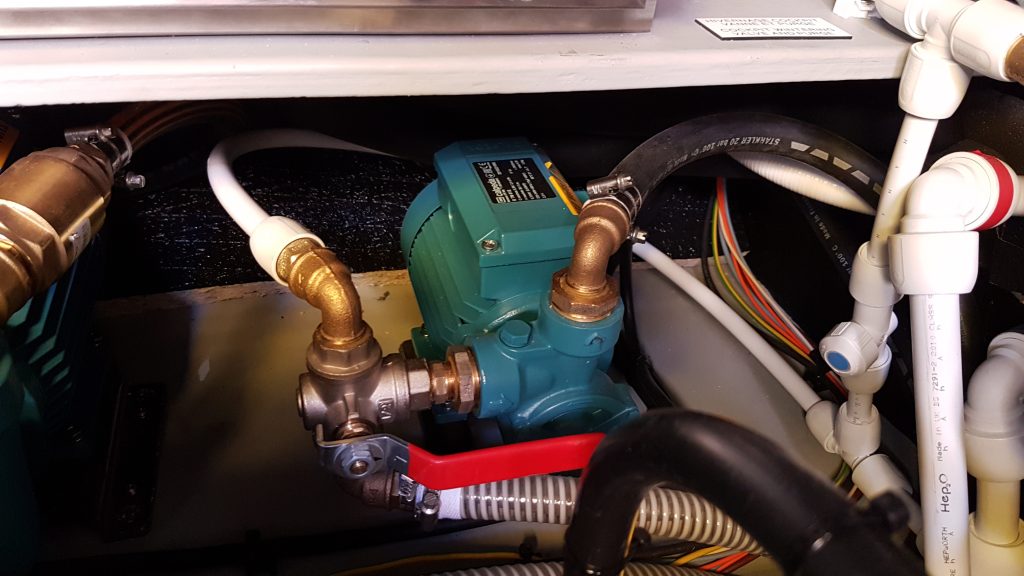

- Rinsing valve (in red on the picture below) :

- Low pressure pump : visible on the picture upon. It takes place under the watermaker. It can be another model than the one on the picture, which is black. Its fuse is located behind the control panel, visible on the picture below.

- High pressure pump : it located behind the control panel. There is no particular maintenance on it except a control of the oil level. This oil needs to be changed every 500hrs… which is an important period for a watermaker. See the picture below :

- Control panel : you can see the regulating valve in a red box on the picture below, and the selection switch on the yellow box :

- Remote : installed on the AMEL 55 et 64 in the kitchen. Picture below :

- Water quality sensor : it is located behind the control panel and controls the salinity of the water. It conditions the redirecting of the water to the water tank or outside. It is visible in the yellow box on the picture below :

Here is a description of the initialization process of the watermaker :

- The rinsing valve opens automatically and operates a first prime of the circuit. This cycle lasts approximately 10 secondes. You need to be sure that the fresh water pump is on and that there is some water in the tank. You can here see that the dial hand of the low pressure manometer is in the green zone.

- Right after that, the low pressure pump starts et runs 15 seconds to keep on priming the circuit. The pressure shown on the low pressure manometer must remains in the green zone.

- Then the high pressure pump starts. The pressure in the circuit is shown by the high pressure manometer and depends on the setting of the regulating valve.

- During all this process, the quality sensor checks the quality and the salinity of the water going out of the membranes. As long as the quality remains “poor”, the water is evacuated outside. Once the optimal pressure is reached, the quality sensor detects it and an automatic system redirects the water toward the tank. At this moment, the pressure inside the machine is very high (about 80 bars).